Though there are plenty of obvious potential dangers working in forestry, there are also hidden threats. Vibration from tools and machines is one of them. If workers regularly and frequently use hand-held power tools and machines, especially for long periods of time, these vibrations can be transmitted into the hands and arms causing permanent harm. The result can be the development of hand-arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS).

Symptoms of HAVS and CTS

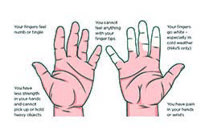

Symptoms include numbing, tingling, lack of feeling, pain and change in colour and strength (see graphic below). The symptoms can come and go, but with continued exposure to hand-arm vibration (HAV), they can become prolonged or permanent. This can happen after only a few months of exposure, but in most cases it will take a few years.

As a result, workers could experience pain, distress and disturbed sleep.

HAV can also make existing hand injuries or other illnesses worse.

People who are exposed to noise and vibration at the same time are more likely to lose their hearing than people who are exposed to noise alone.

If the symptoms are ignored, the damage can become permanent and disabling. As a result, workers may not be able to do simple tasks like opening jars or using a phone. They may have to stop working with vibrating equipment if they can no longer safely handle tools and machines.

Factors affecting HAV exposure level

Different power tools and machines produce different amounts of vibration. Power tools and machines that are older or not well-maintained usually vibrate more.

The use of power tools and machines – typically high vibration ones – is linked to HAVS and CTS. These include using hand-held or hand-guided tools like:

chainsaws,

jackhammers/demolition hammers/demolition breakers,

hammer drills,

jigsaws,

sanders,

hand-held grinders,

weed whackers/line trimmers,

powered sanders,

pneumatic drills,

powered lawn mowers.

As well as in forestry, HAVS and CTS are seen in professions such as metal working, demolition, road repair, construction, heavy engineering and foundries.

There are many factors that can influence the effects of exposure to HAV. These include:

the condition of the power tool/machine,

the vibration intensity,

the duration of exposure (time/day, frequency),

the temperature the work is being carried out in,

operator technique (for example, how hard the worker grips the power tool/machine),

operator health and medical history (including if they smoke).

To work out the risk, think about:

the power tool/machine,

how the work is organised,

the task,

the workers.

The recommended maximum daily amount of HAV that workers should not exceed is eight hours. Control measures should be put in place if workers are exposed to an eight hour average or more.

Role of the power tool/machine

What is the vibration level of the power tool/machine?

– See the manufacturer’s user manual or specification.

Is the power tool/machine regularly maintained?

– There is greater vibration when power tools and machines are not well maintained.

– Blunt tools mean tasks take longer, meaning more exposure to vibration.

Is it a heavy hand-held power tool/machine?

– Tighter grip is needed for heavier power tools and machines. Gripping too tightly increases the chances of developing HAVS or CTS.

Does a large area of the hand contact the power tool/machine?

– The larger the areas of contact,...